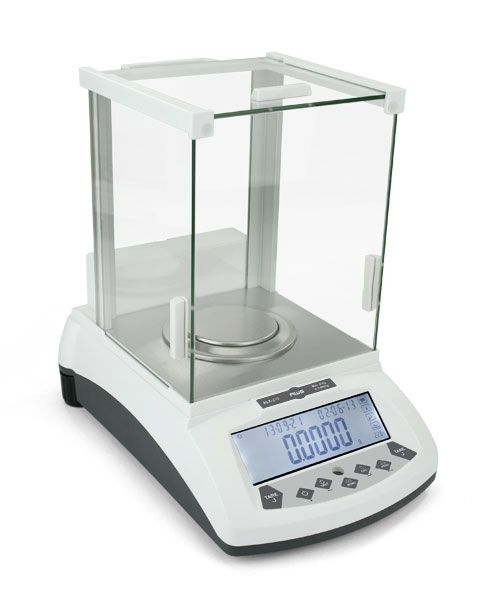

A digital weighing balance is one of the most important instruments used in laboratories, industries, and research facilities. To get accurate and reliable results, regular digital weighing balance calibration is essential. If a weighing balance is not calibrated properly, it can lead to errors in measurements, poor data quality, and even compliance issues in regulated industries.

This weighing balance calibration guide will walk you through everything — from understanding its importance to a step-by-step weighing balance calibration procedure.

Importance of Weighing Balance Calibration

Calibration of weighing balance is the process of checking and adjusting the balance to ensure it provides accurate readings. Here’s why it matters:

-

Ensures measurement accuracy

-

Helps in meeting quality and compliance standards

-

Prevents costly errors in experiments or production

-

Extends the life of the equipment

-

Improves confidence in laboratory data

Regular weighing balance calibration frequency depends on your usage, environment, and regulatory requirements. Many labs calibrate daily, weekly, or monthly.

How to Calibrate a Digital Weighing Balance

Step-by-Step Weighing Balance Calibration Procedure

Clean the balance

-

Gently wipe the weighing platform with a clean, lint-free cloth.

-

Make sure no dust or spilled chemicals remain.

Warm up the instrument

-

Turn on the balance and let it stabilize for 15–30 minutes.

Level the balance

-

Check the leveling bubble indicator and adjust the feet of the balance if needed.

Select proper calibration weights

-

Use standard certified weights that match the balance’s capacity.

Zero the balance

-

Press the “TARE” or “ZERO” button to reset the display to zero.

Place the calibration weight

-

Carefully place the standard weight at the center of the pan.

-

Allow the reading to stabilize.

Adjust or record readings

-

If the reading is not accurate, follow the weighing balance calibration steps as per the manufacturer’s instructions to adjust it.

Repeat for multiple points

-

Calibrate at different weight levels (e.g., 10%, 50%, and 100% of capacity) for more accurate results.

Complete documentation

-

Record all results in your daily weighing balance calibration checklist or logbook.

How to Check Weighing Balance Accuracy

Digital balance accuracy testing can be done by placing known standard weights and checking if the balance displays the exact weight. If there’s a deviation, it must be recalibrated or serviced. Routine laboratory weighing balance calibration ensures consistent performance.

Tips for accuracy checking:

Always use calibrated weights.

Keep the balance away from air drafts, vibrations, and temperature fluctuations.

Check before and after critical measurements.

Weighing Balance Troubleshooting and Maintenance

Even with proper calibration, digital balances may sometimes give inaccurate readings. Here are some weighing balance troubleshooting and maintenance tips:

Re-calibrate if the balance was moved or if environmental conditions changed.

Check if the platform is clean and stable.

Ensure no electrical interference is present.

Regularly service your balance as per the manufacturer’s instructions.

By following these best practices for digital balance calibration, you can extend the instrument’s life and maintain high accuracy.

Weighing Balance Calibration Frequency and Records

The weighing balance calibration frequency should be defined based on:

-

How often the balance is used

-

The required precision of measurements

-

Regulatory requirements in your industry

Most laboratories perform daily weighing balance calibration or at least before critical tests. Keeping calibration records helps in quality audits and traceability.

Calibration Tips for Laboratory Weighing Balances

-

Always calibrate at the same location where the balance will be used.

-

Use proper certified calibration weights.

-

Avoid touching weights with bare hands to prevent contamination.

-

Keep the environment clean and stable.

-

Train your staff on easy methods to calibrate weighing balance correctly.

ConclusionCalibration of weighing machine is not just a technical task — it’s a quality assurance practice. By following this weighing balance calibration guide and maintaining proper records, you can ensure accurate, reliable, and traceable measurements in your lab or industry.

Regular electronic weighing balance calibration builds confidence in your results, helps in meeting compliance standards, and protects your investment in laboratory equipment.